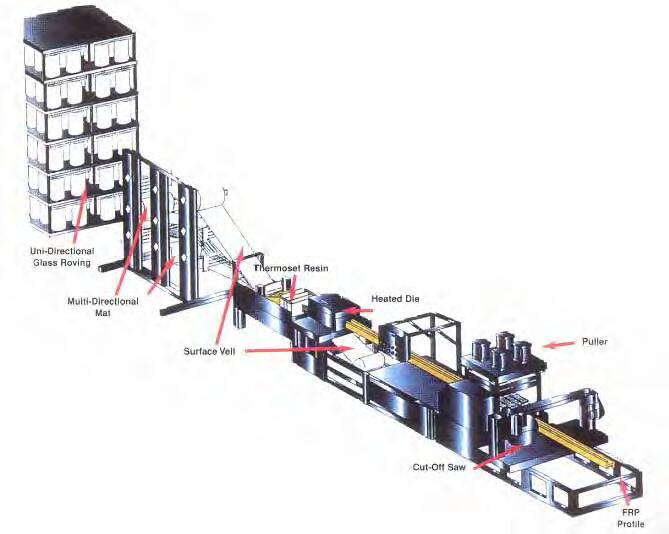

Pultrusion is the continuous processing of raw materials by pulling resin-rich reinforcements

through a heated steel die to form profiles of constant cross section of continuous length.

Pultrusion gets its name from the method by which the profiles are made. Raw materials are

literally pulled by what is called the “puller.” The puller is the machine made of pulling pads,

which grip the product, and a drive system that keeps the product moving. The puller is located

just before the cut-off saw.

The process starts with the reinforcements. Typically, unidirectional glass roving begins the

process. This is the fiber that runs along the length of the profile. Then, the fiberglass mat is

added, which is a multidirectional reinforcement. Next, the glass reinforcements are “wet-out”

with a thermoset resin, typically polyester or vinylester. Finally, just before all the material is

pulled into the heated die, surface veil may be added to enhance the surface appearance of the

final product.

Next in the pultrusion process is the curing of the composite. The curing or hardening occurs

while the wet-out reinforcements are being pulled through the heated die. The heat from the die

causes the resin to cure and by the time the part exits the die, a hard part in the exact shape of the

die cavity has been formed. The final result is a solid, rigid profile with all the reinforcements

laminated within.

The puller then pulls the product exiting the die to the cut-off saw, which cuts it to the desired length.

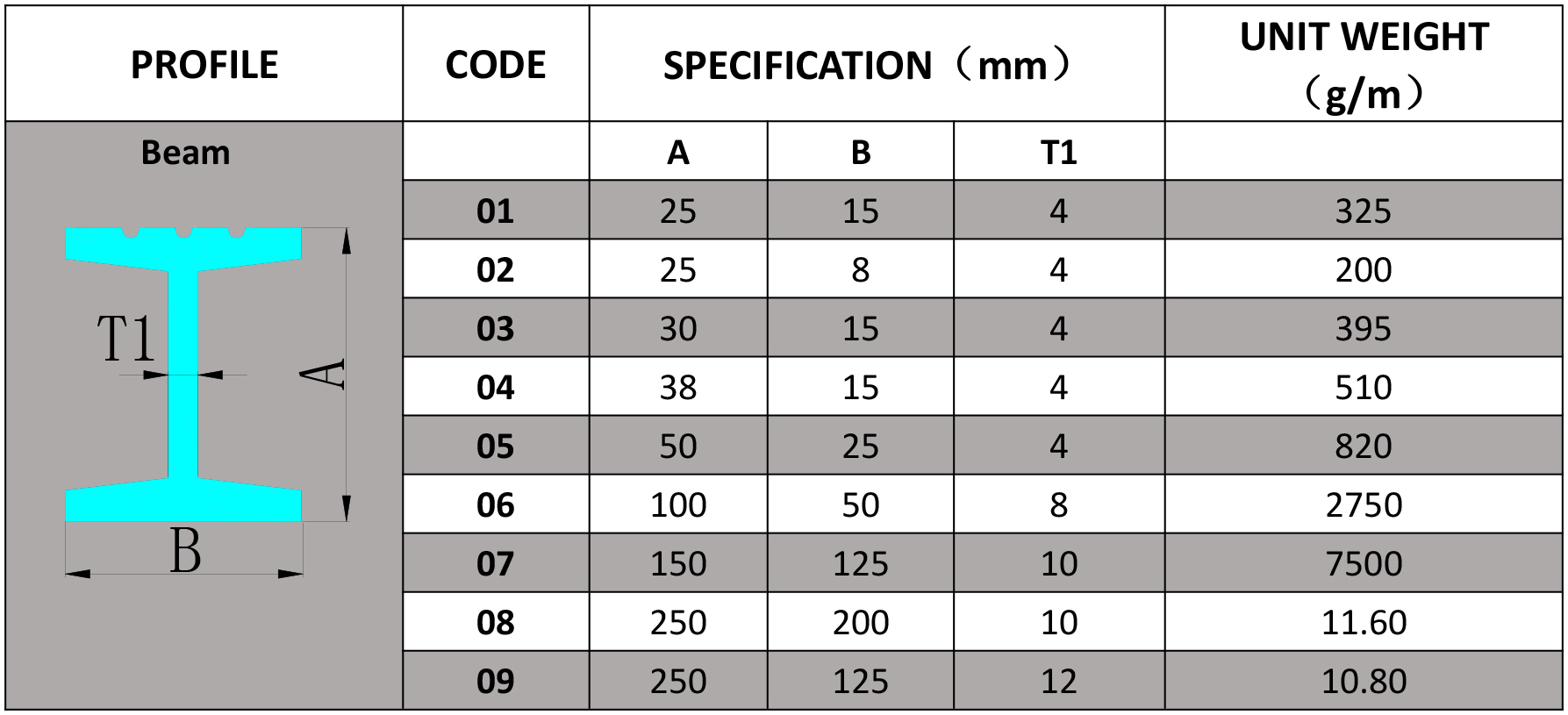

Specification:

Experience

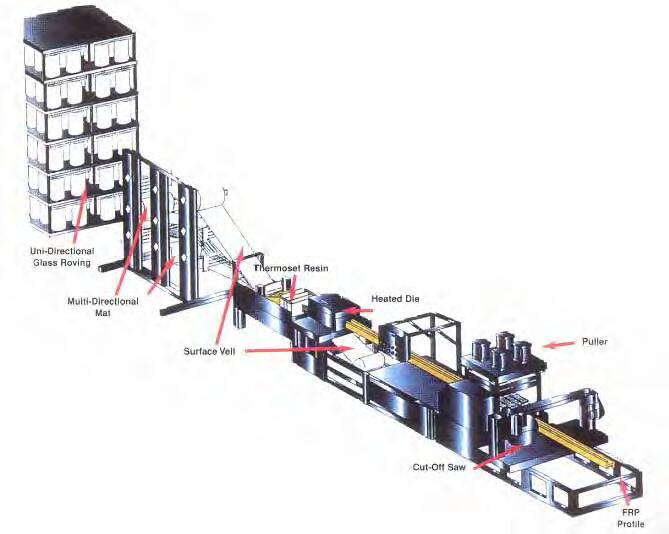

Pultrusion is the continuous processing of raw materials by pulling resin-rich reinforcements

through a heated steel die to form profiles of constant cross section of continuous length.

Pultrusion gets its name from the method by which the profiles are made. Raw materials are

literally pulled by what is called the “puller.” The puller is the machine made of pulling pads,

which grip the product, and a drive system that keeps the product moving. The puller is located

just before the cut-off saw.

The process starts with the reinforcements. Typically, unidirectional glass roving begins the

process. This is the fiber that runs along the length of the profile. Then, the fiberglass mat is

added, which is a multidirectional reinforcement. Next, the glass reinforcements are “wet-out”

with a thermoset resin, typically polyester or vinylester. Finally, just before all the material is

pulled into the heated die, surface veil may be added to enhance the surface appearance of the

final product.

Next in the pultrusion process is the curing of the composite. The curing or hardening occurs

while the wet-out reinforcements are being pulled through the heated die. The heat from the die

causes the resin to cure and by the time the part exits the die, a hard part in the exact shape of the

die cavity has been formed. The final result is a solid, rigid profile with all the reinforcements

laminated within.

The puller then pulls the product exiting the die to the cut-off saw, which cuts it to the desired length.

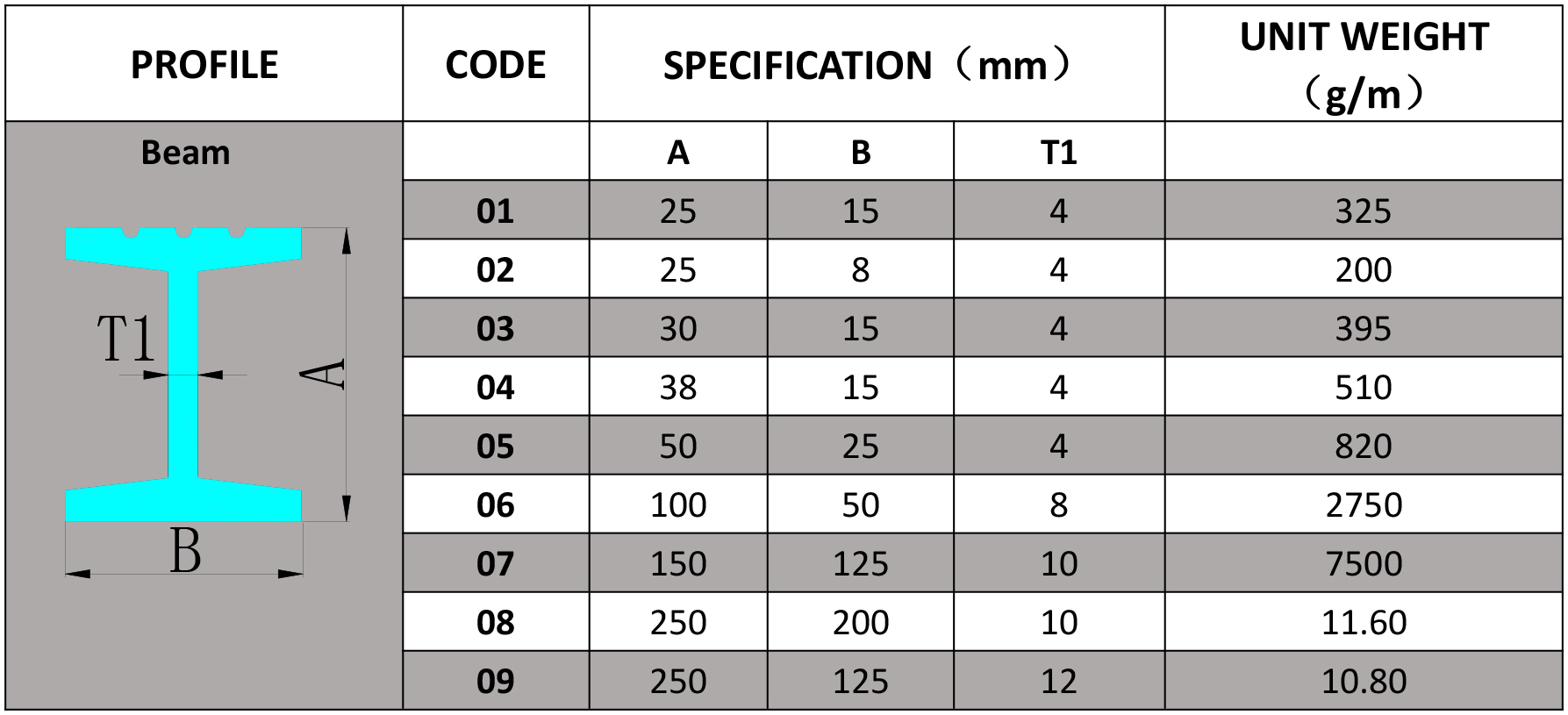

Specification: