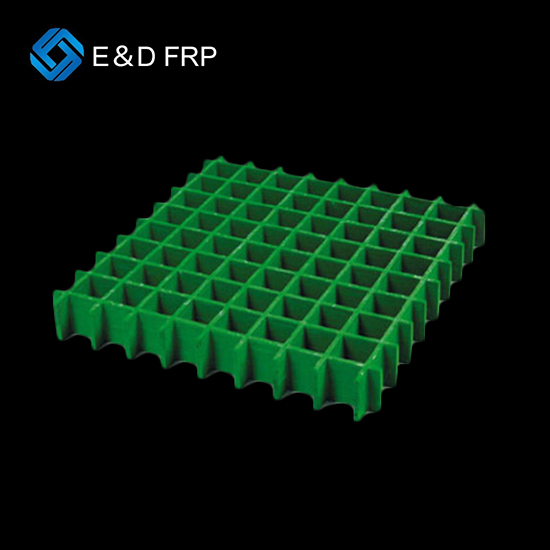

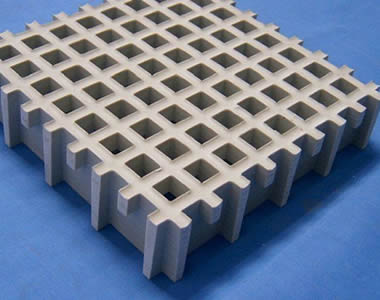

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction

of vertical and horizontal, and thurougly wetted out with resin, layer by layer. When the weaving

process is completed, the mould is heated to cure the panel.

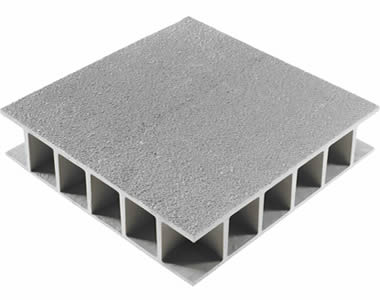

After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave)

top surface. Any process such as post applied grit could be bonded after as a secondary operation.

This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

Resin systems:

Ortho Resin:General choice resin system in FRP Mould Grating production.good corrosion resistance with lower cost.

ISO Resin: High thermal stabilty,High chemical resistance,tough,low shrinkage,excellent electrical insulation properties.

Vinyl ester: excellent chemical resistance,very good physical properties good temperature performance

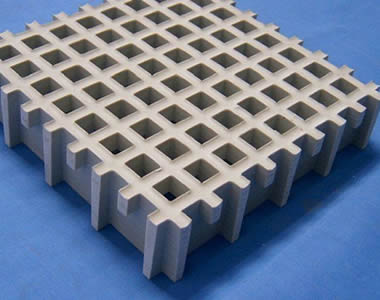

Surface type:

1.common surface type:

FRP gratings with polished smooth surfaces FRP gratings with sanding surfaces FRP gratings with concave surfaces

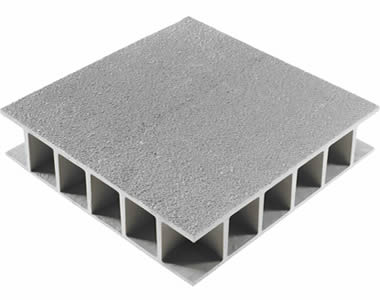

2.Covered surface type:

The gritted top covered surface The diamond shape surface

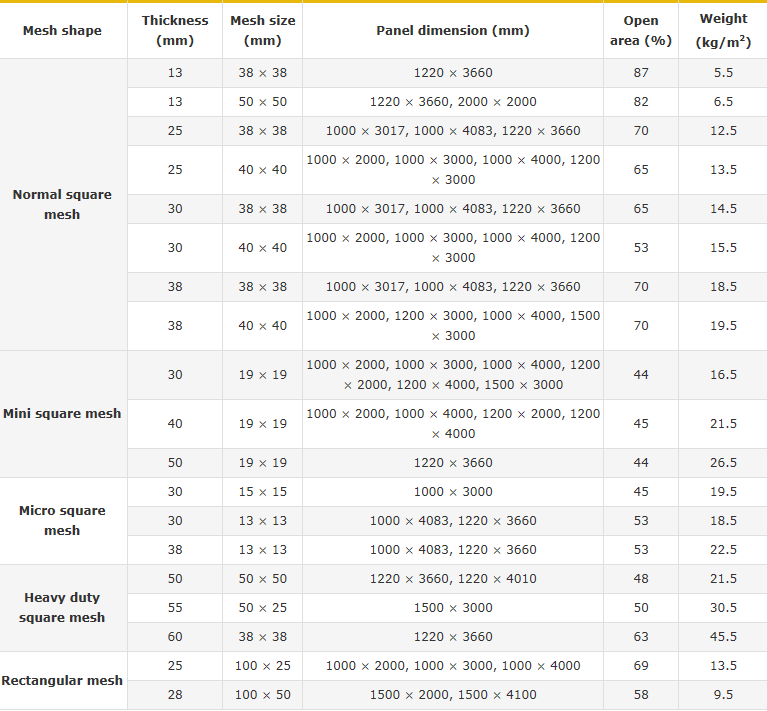

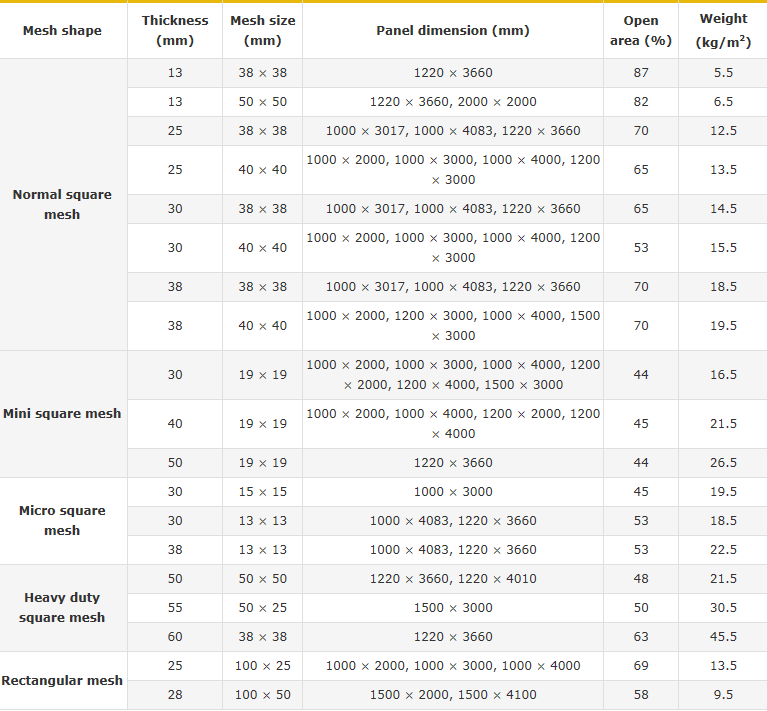

Specification:

Featurepe:

• Longer lasting materials require fewer resources for replacement.

• Reduced maintenance and repair costs.

• Lightweight panels use 90% less material than precast

• Lightweight panel reduces fuel and costs of transportation

• Unique manufacturing process applies color in the factory and delivers a quality finish, virtually eliminating VOCs during exterior painting.

• The low thermal conductivity of fiberglass reduces energy consumption for heating and cooling.

Applicication:

Experience

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction

of vertical and horizontal, and thurougly wetted out with resin, layer by layer. When the weaving

process is completed, the mould is heated to cure the panel.

After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave)

top surface. Any process such as post applied grit could be bonded after as a secondary operation.

This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

Resin systems:

Ortho Resin:General choice resin system in FRP Mould Grating production.good corrosion resistance with lower cost.

ISO Resin: High thermal stabilty,High chemical resistance,tough,low shrinkage,excellent electrical insulation properties.

Vinyl ester: excellent chemical resistance,very good physical properties good temperature performance

Surface type:

1.common surface type:

FRP gratings with polished smooth surfaces FRP gratings with sanding surfaces FRP gratings with concave surfaces

2.Covered surface type:

The gritted top covered surface The diamond shape surface

Specification:

Featurepe:

• Longer lasting materials require fewer resources for replacement.

• Reduced maintenance and repair costs.

• Lightweight panels use 90% less material than precast

• Lightweight panel reduces fuel and costs of transportation

• Unique manufacturing process applies color in the factory and delivers a quality finish, virtually eliminating VOCs during exterior painting.

• The low thermal conductivity of fiberglass reduces energy consumption for heating and cooling.

Applicication: